NASA

NASA-Developed Printable Metal Can Take the Heat

NASA’s Breakthrough: Printable Metal Ready for Space Heat

What’s Happening?

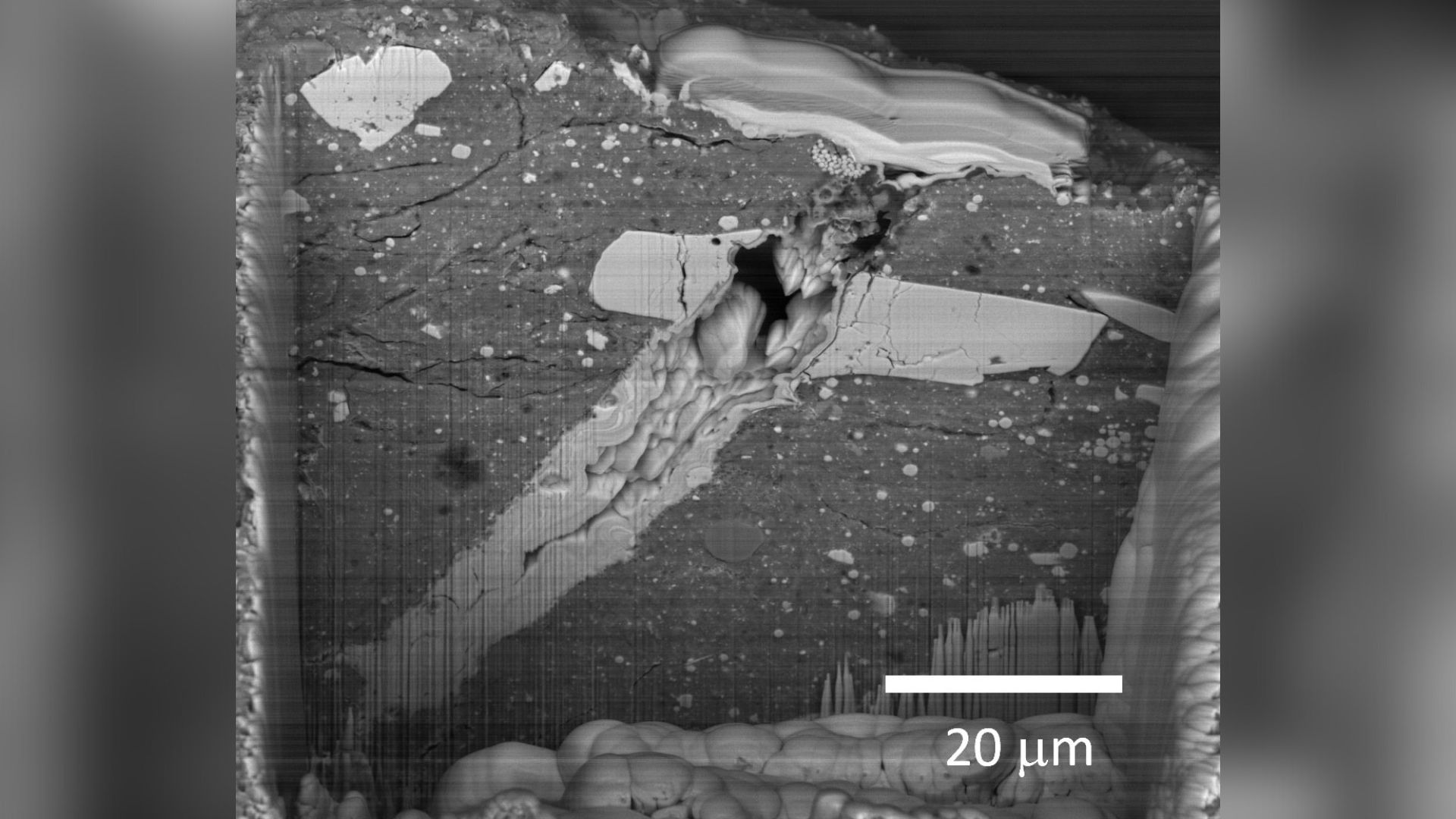

NASA engineers have developed an innovative metal alloy designed specifically for 3D printing that can withstand the scorching temperatures of spaceflight. This breakthrough could revolutionize the way spacecraft components are manufactured, making them stronger, lighter, and more affordable.

Where Is It Happening?

The research is being conducted at NASA’s Glenn Research Center in Cleveland, Ohio. The implications of this technology have global significance for the aerospace industry and future space missions.

When Did It Take Place?

The development of this printable metal alloy is part of ongoing research, with recent advancements highlighting its potential for space applications.

How Is It Unfolding?

– NASA’s new metal alloy can endure extreme temperatures, a critical requirement for spaceflight components.

– The development opens up possibilities for more affordable and efficient manufacturing of rocket engines and spacecraft parts.

– Researchers focused on overcoming the limitations of traditional metal 3D printing techniques.

– The alloy could lead to lighter, more durable, and cost-effective aerospace technologies.

Quick Breakdown

– Metal alloy developed by NASA for 3D printing.

– Withstands extreme temperatures of spaceflight.

– Potential to revolutionize aerospace component manufacturing.

– Research conducted at NASA’s Glenn Research Center.

– Could make rocket engines and spacecraft parts more affordable.

Key Takeaways

NASA’s new printable metal alloy marks a significant milestone in additive manufacturing for the aerospace industry. By overcoming the temperature limitations of traditional 3D printing, NASA paves the way for more efficient and cost-effective production of spacecraft components. This innovation could lead to stronger, lighter parts that are crucial for exploring the harsh environments of space, making space travel more feasible and economical.

This alloy is a game-changer. It not only meets but exceeds the thermal demands of space technologies, potentially redefining how we explore beyond Earth.

– Dr. Emily Hart, Aerospace Materials Expert

Final Thought

NASA’s breakthrough opens a new era in additive manufacturing, where the limitations of temperature no longer hinder the production of spaceflight components. This technology promises to cut costs, enhance performance, and accelerate advancements, bringing humanity closer to uncharted territories of the cosmos. The future of space exploration just got a whole lot hotter—and stronger.

Source & Credit: https://www.enn.com/articles/76953-nasa-developed-printable-metal-can-take-the-heat